Jan 28, 2026

akenza partners with Hilscher to bring industrial data to the cloud

Alexis Leibbrandt

Your factory floor is full of valuable data. But it’s often locked in place.

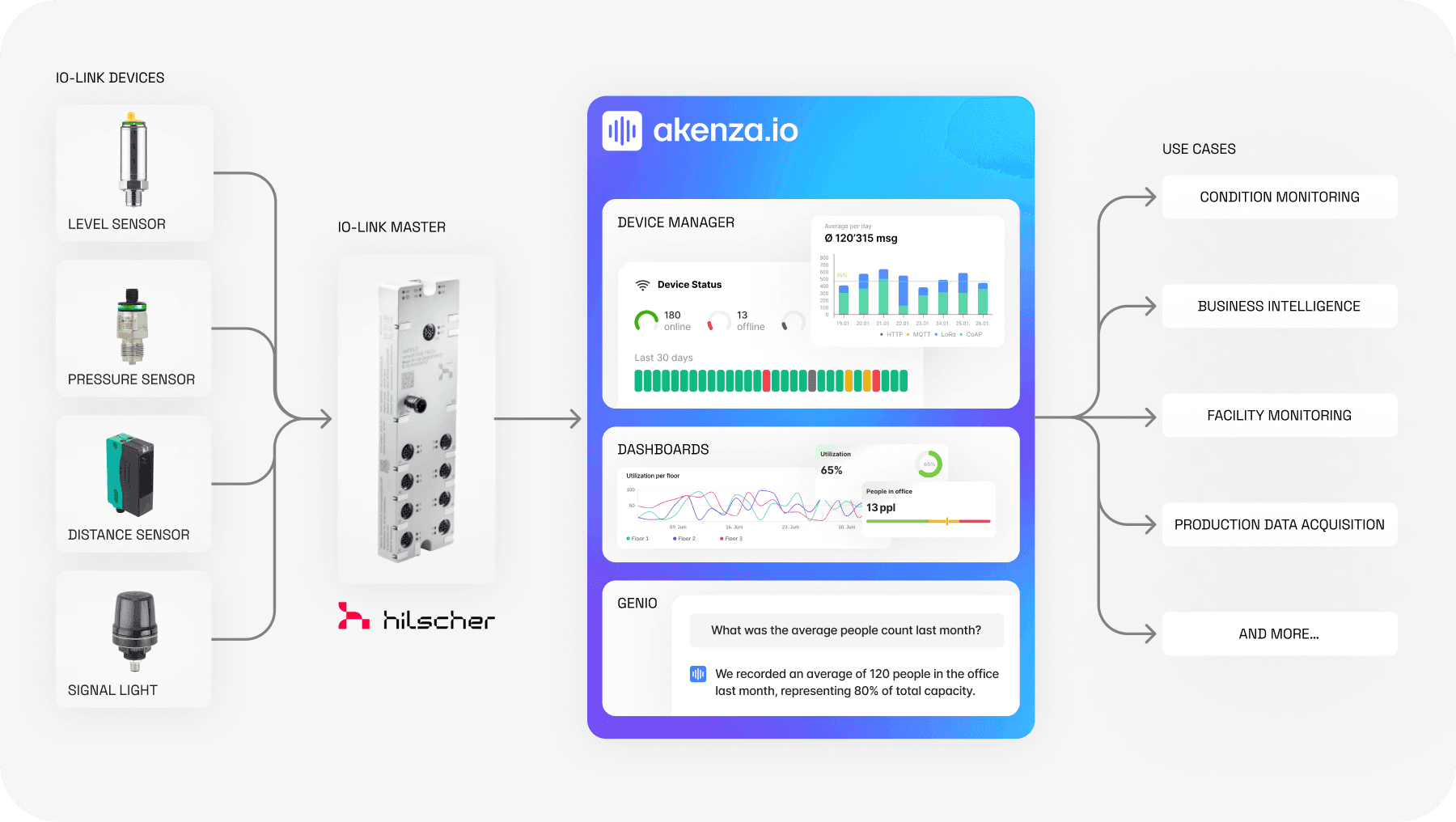

Our partnership with Hilscher changes that. We’ve successfully integrated Hilscher’s sensor EDGE FIELD IO-Link Master into the akenza platform, making it possible to extract sensor and actuator data from the field level and bring it to the cloud without touching your existing automation systems.

The industrial data paradox

In most manufacturing facilities, sensors and actuators at the field level collect rich, real-time data. But accessing it means interfacing with PLCs, SCADA systems, which requires significant engineering.

This creates lengthy engineering projects, operational risk, and high costs. IT and OT teams must coordinate carefully, and any misstep could impact production.

A non-intrusive path to your data

Hilscher and akenza are bringing a solution to this. By integrating Hilscher’s IO-Link Master with the akenza IoT platform, we’ve created a data path that runs parallel to your existing automation infrastructure and routes data from IO-link devices to the cloud. This means you can access sensor data from the field level without interfering with PLC logic, SCADA systems, or any mission-critical operations.

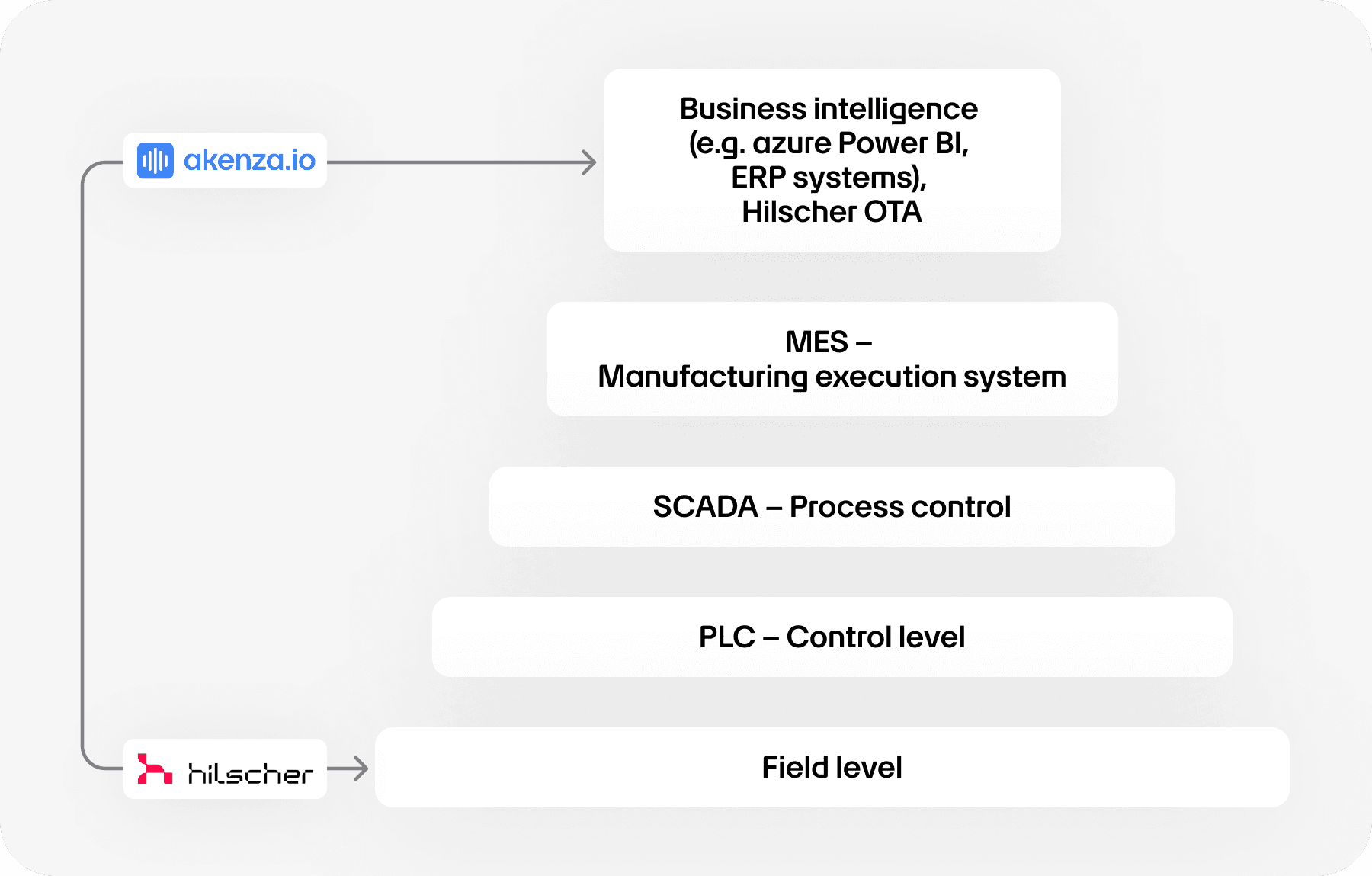

ISA-95 Automation Pyramid

Why IO-Link?

IO-Link is a widely adopted industrial standard for point-to-point communication. IO-Link delivers vendor-agnostic connectivity and supports the transfer of rich, structured data (beyond simple on/off signals or analogue values).

The technical foundation

Hilscher’s sensorEDGE FIELD serves as the bridge between your IO-Link devices and the akenza IoT platform. As a full-featured edge device with Docker container support and over-the-air (OTA) updates, it does more than just collect data. It enables you to run local applications at the edge while seamlessly forwarding data to akenza, creating a future-proof architecture that can adapt to evolving security requirements, compliance standards, and industrial use cases.

In akenza, your IO-Link data is unified into one data layer and combined with information from other sources (LPWAN sensors, BMS systems, existing databases). The data can then be visualised via personalized dashboards, trigger custom rules and actions, and integrated with your existing business intelligence tools via REST API, or webhooks.

Built for brownfield and retrofit

If you already have an automation infrastructure in place, connecting to akenza is straightforward. Adding an Hilscher IO-Link Master with the corresponding IO-Link sensors to your existing infrastructure is all it takes.

This makes the solution ideal for brownfield environments or for retrofit projects.

Expand to new use cases without replacing existing systems

This solution doesn’t replace your PLC, SCADA, or MES. Instead, it complements them by creating a separate data path for cloud-based use cases such as Condition monitoring, Business intelligence, or facility monitoring.

Bridge OT and IT. Keep operations running.

The partnership between Hilscher and akenza represents a practical approach to Industrial IoT: extract the data you need, enable new capabilities, without disrupting what’s already working on your shop floor.

Your industrial data shouldn’t be locked away. With Hilscher’s connectivity expertise and akenza’s IoT platform, it doesn’t have to be.

Discover other blog posts

Need help with your IoT project?

To learn more about how akenza can help you build smart solutions with ease, contact us or directly sign up for a free trial today.

Changelog

If you want to follow the latest updates and upcoming features of akenza in real-time, be sure to check our changelog.